We show how we produce

Production is the “beating heart” of all Vion slaughtering and processing companies. Our highly trained employees work together with government veterinarians, inspectors and livestock farmers to comply with production and hygiene regulations, day in day out.

In this video, we show how pigs are slaughtered and processed. Veterinarian and quality director of Vion Netherlands Derk Oorburg explains what we see.

(This video is in German)

The pigs are driven to the abattoir by specially trained drivers.

When they are unloaded, an official veterinarian checks whether the pigs are healthy.

First, the pigs are allowed to recover from their journey in a stable.

The pigs are carefully led into the sedation unit in groups.

Using gentle persuasion, groups of pigs in turn are led into the sedation unit.

In the gondola, the animals are put under a CO2 atmosphere for more than two minutes, until they are fully anaesthetised. For more information on the sedation process, visit: www.eyesonanimals.com/nl/verdoving-van-varkens-voor-de-slacht/

The fully anaesthetised pigs roll out of the sedation unit.

To make sure that the animals are fully sedated, specially trained staff check the eyelid reflex.

The sedated animal is killed by means of stabbing.

Blood samples are taken from each delivery of animals for slaughter. These provide information on the health of the pigs and the general status of the farm.

The carcass is placed in a hot bath at 60 degrees for 6 to 8 minutes. This loosens the bristles on the skin/hide.

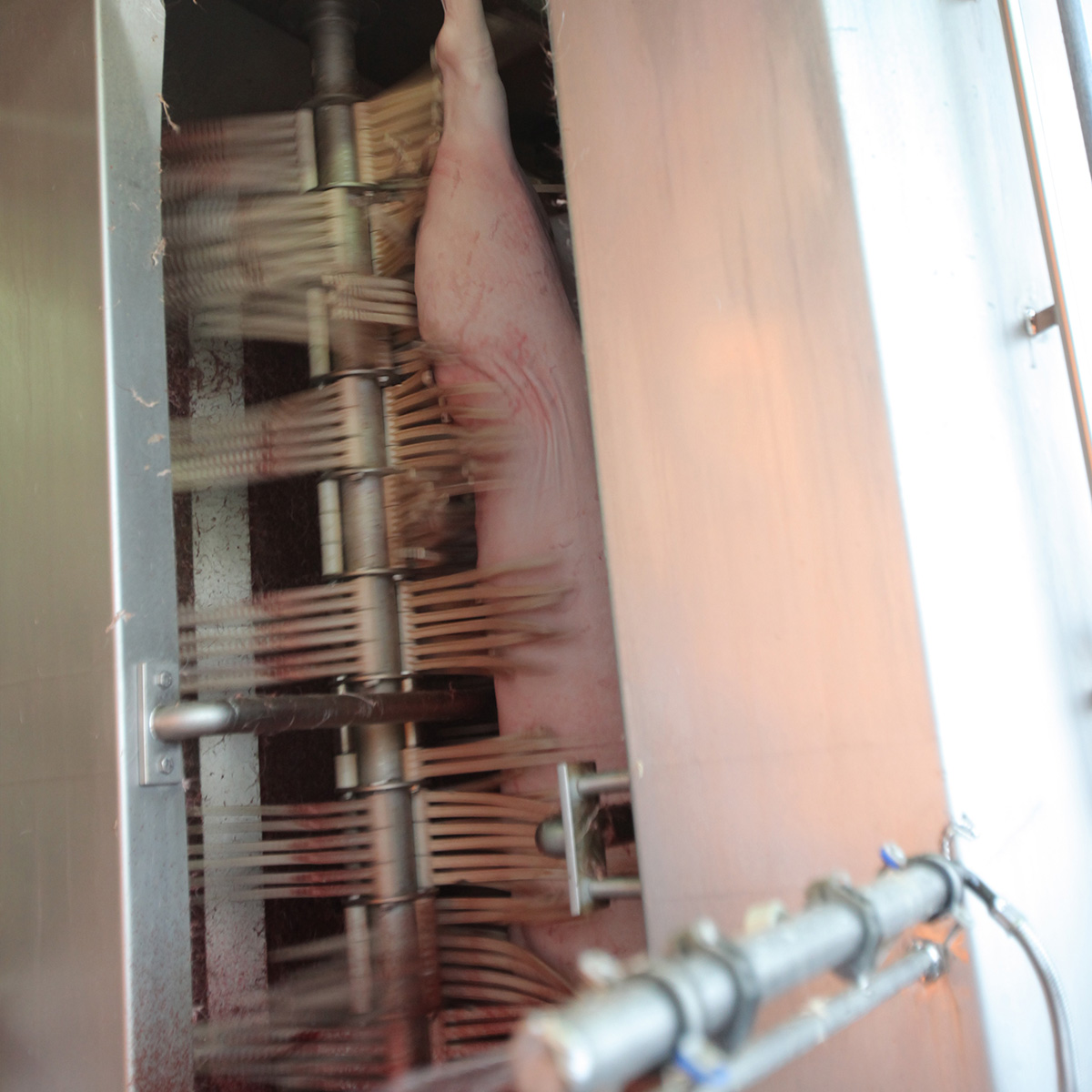

Most of the bristles are removed from the carcass in the brushing machine.

The last remaining bristles are burned off. The heat also kills any bacteria on the surface of the carcass.

The animal is hung by its hind legs for further processing.

The gastrointestinal tract is removed hygienically. The intestines are used to make sausage, among other things.

The heart, lungs and trachea are also removed. These are also used later. Nowadays, mainly in the production of dog food.

After the organs have been removed, the carcass is sawn into two halves.

Official, independent veterinarians and inspectors check whether the carcass is suitable for consumption.

The organs are also carefully examined for signs of disease.

A sample is taken from each carcass to be tested for Trichinella in connection with food safety. This is part of a much larger test programme in the meat industry, which includes tests for heavy metals, antibiotics and other chemicals.

The sample is examined in the laboratory for the presence of Trichinella.

Carcasses with defects are sent to a separate platform. Here, the defects are cut out (these are not suitable for consumption) and the carcass is inspected again by an official inspector.

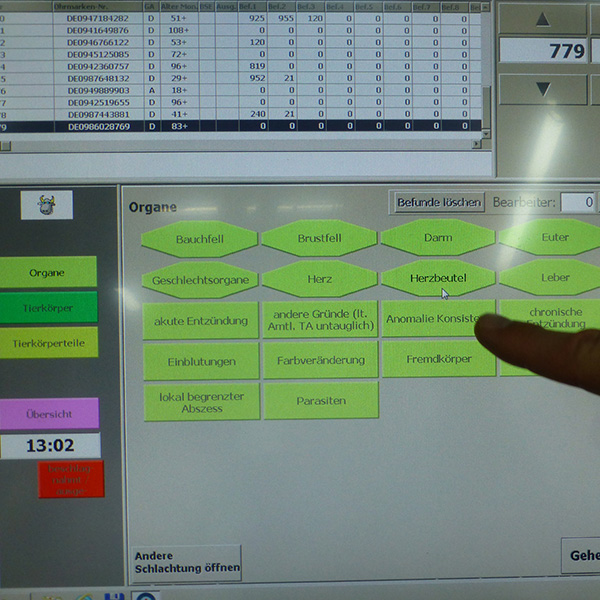

The computer records the ear tag numbers and links them to the carcass hook numbers. This means that each carcass can be traced back to the livestock farmer.

Carcasses that are suitable for consumption are given an official stamp. This stamp contains the EC number and indicates that the carcass has been approved.

The carcasses are cooled from 37 degrees body temperature to below 7 degrees.

After cooling, the rough cutting of the carcasses into ham, shoulder and middle parts begins.

The parts of the pig may then be further subdivided, for example into belly meat, loin ribs, spare ribs or scraps for sausage production.

The cut pieces are packaged.

Vion Retail Groenlo and Vion Grossostheim specialise in the production of consumer products. Minced meat, pork chops and other retail items are produced, packaged, labelled and loaded in Groenlo and Grossostheim.

Processed meat products are produced at Encebe Vleeswaren.

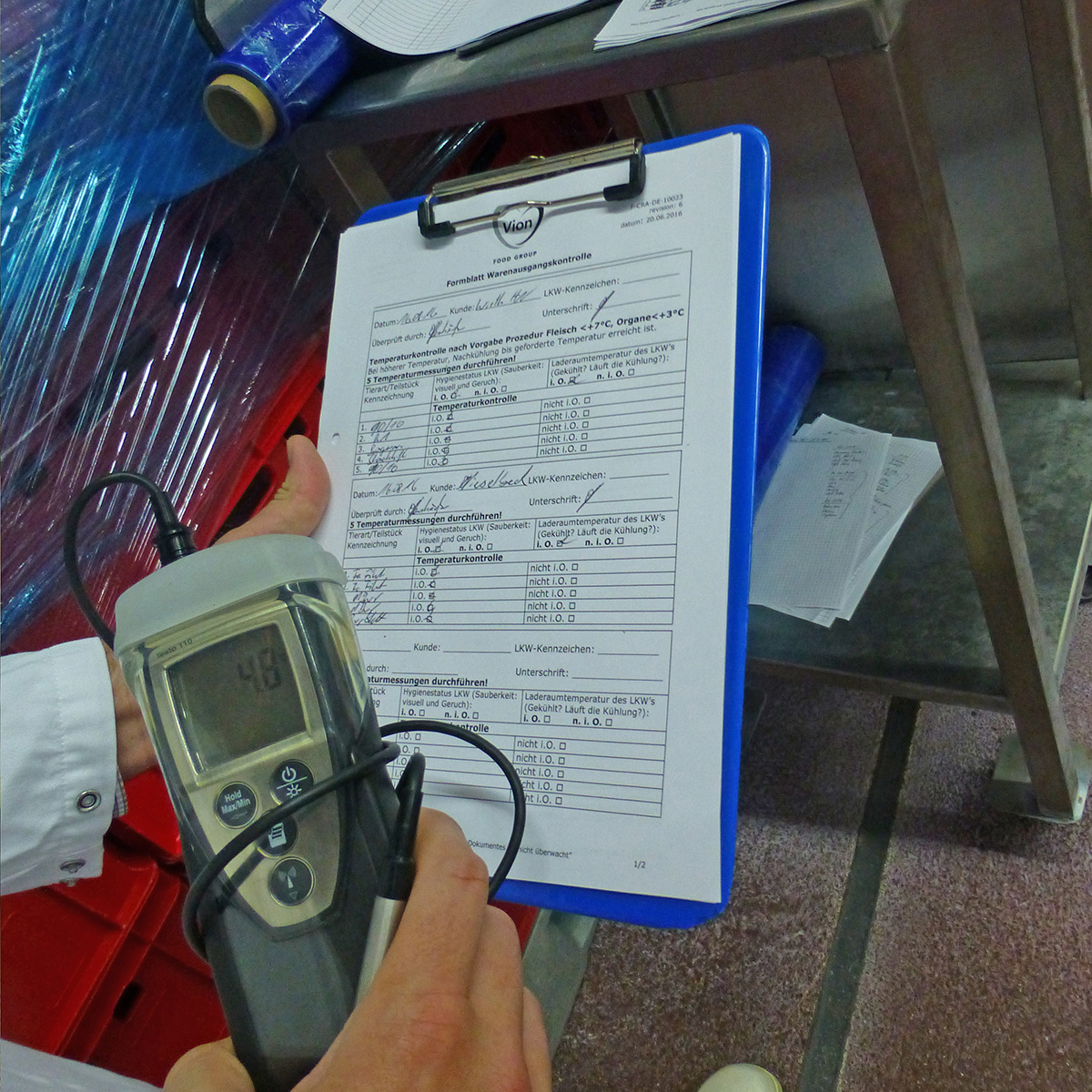

Only optimally cooled products may leave the company. This is checked by the expedition department. This department records all important data.

The products are transported to customers in clean and cooled trucks.

In this video, we show how cattle is slaughtered and processed. This is explained by Dr. Anne Hiller, veterinarian and quality director of Vion Germany.

(This video is in German)

Photo report on the production of beef

The cattle are driven to the abattoir by specially trained drivers.

A supervising veterinarian examines each animal individually while they are being unloaded and determines whether they are all healthy. If anything is wrong, the animal is set aside.

The small herd is first led to the stable first, where they can settle down.

After about two hours, the group of cattle is carefully led to the stunning box.

The cattle enter the stunning box one by one. The head is secured. In this way, trained employees can stun the animals, using a captive bolt stun gun, with great precision.

The unconscious animal rolls out of the stunning box. An employee checks the eyelid reflex to make sure that the animal is completely unconscious.

The sedated animal is killed by means of stabbing. They are then hung up and allowed to bleed dry.

The carcasses, which are hung by their legs, are transported along a rail. The heads are cut off.

The computer records the ear tag numbers and links them to the carcass hook numbers. This means that each carcass can be traced back to the livestock farmer.

The hide is removed from the carcass.

The hides are made into leather in a tannery. Industrial gelatine is also made from the hides.

The gastrointestinal tract is removed hygienically.

The heart, lungs and trachea are also removed.

The carcass is divided into two parts

On the inspection platform an official independent veterinarian and inspector checks whether the animal was healthy.

All of the animal’s organs are also examined for abnormalities.

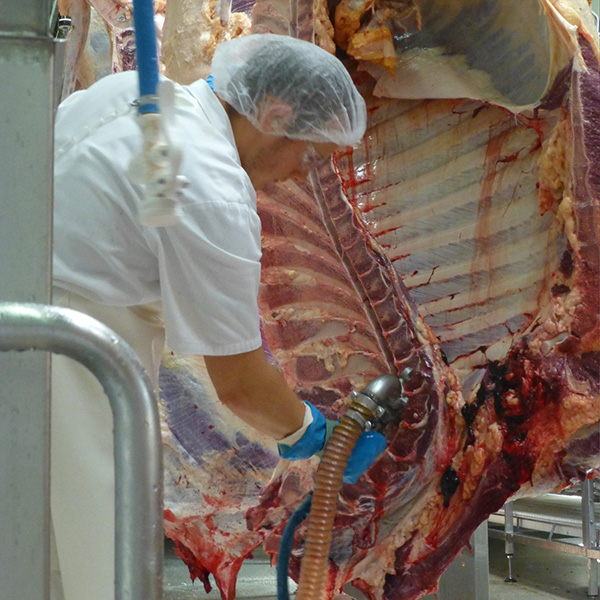

A so-called “vacuum cleaner” is used to remove the spinal cord from the spinal column. It is then examined to check whether BSE pathogens are present in the spinal cord.

Irregularities, such as growths or blemishes, are cut out.

Employees of BV CBS (an independent organisation that carries out classifications in the livestock and meat sector) determine the quality level of the carcass. The classification of the carcass and its weight determine the price the supplier receives for the beef.

The veterinarian confirms that the meat is suitable for consumption with a stamp.

The carcass is labeled with information on its origin, weight, slaughter details and quality level.

Immediately after slaughter, the carcasses are cooled from 37 degrees body temperature to below 7 degrees. At the customer’s request, the beef can be matured for two to four weeks in cold storage. Particularly tender dry-aged cuts can even ripen for up to six weeks.

The carcasses are divided into quarters for further processing or transport.

The hind cuts of beef are of the highest quality. Minced meat is made from the front quarters, for example.

Vion Enschede, Vion Retail Groenlo and Vion Grossostheim specialise in the production of consumer products. This is where, for example, steak, minced meat and other beef products are produced, packaged, labelled and loaded.

Only optimally cooled products may leave the company. This is checked by the expedition department. This department records all important data on a form.

The products are transported to customers in clean and cooled trucks.